In today’s dynamic and uncertain world, businesses face a plethora of challenges, with one of the most prominent being the unpredictable nature of process variations. These variations can disrupt even the most well-established workflows, potentially leading to costly delays and errors. Developing effective contingency plans for managing random process variations is crucial for maintaining operational resilience and ensuring business continuity. In this article, we will explore a comprehensive approach to developing contingency plans that can help businesses thrive in an ever-changing environment.

Category Archives: business process improvement

Are Your Processes Profit Vampires? Find Out With a Process Cost Analysis.

In today’s dynamic and competitive business environment, every organization strives to maximize its efficiency, reduce costs, and enhance profitability. One powerful tool that helps achieve these objectives is process cost analysis. In this article, we will delve into the intricacies of conducting a process cost analysis and emphasize its significance in optimizing operations and decision-making.

Want to Close Business Deals Faster? Automate your Request For Proposal Process.

In today’s dynamic and competitive business world, closing deals swiftly can make all the difference. The ability to streamline your processes, especially when it comes to Request for Proposals (RFPs), can significantly reduce the time it takes to finalize important agreements. RFPs are a fundamental part of the business world, but the traditional manual approach can be time-consuming and resource-intensive. In this article, we will explore how to expedite business deal closures through RFP template automation, helping you gain a competitive edge and achieve faster results.

The Hidden Culprit: How Set-Up Time Causes Waste in Processes and Businesses

In today’s fast-paced business environment, efficiency and productivity are paramount. Organizations strive to streamline their processes, eliminate waste, and optimize resource utilization. However, there’s a hidden culprit that often goes unnoticed – set-up time. The time it takes to prepare a machine, system, or workflow for production can be a significant source of waste. In this article, we will explore the various ways in which set-up time can lead to inefficiencies, increased costs, and reduced competitiveness for businesses. We’ll also discuss strategies to minimize set-up time and its associated waste.

Boosting Productivity, Customer Satisfaction, and Profitability by Eliminating Non-Value Added Activities

In the relentless pursuit of success, businesses must constantly seek ways to improve their efficiency, customer satisfaction, and profitability. One often-overlooked factor that can significantly impact these aspects is the presence of non-value added activities within an organization. These activities, while seemingly innocuous, can have a profound negative impact on overall performance. In this blog post, we will delve into the world of non-value added activities, uncovering how they can stunt productivity, erode customer satisfaction, and hinder profitability.

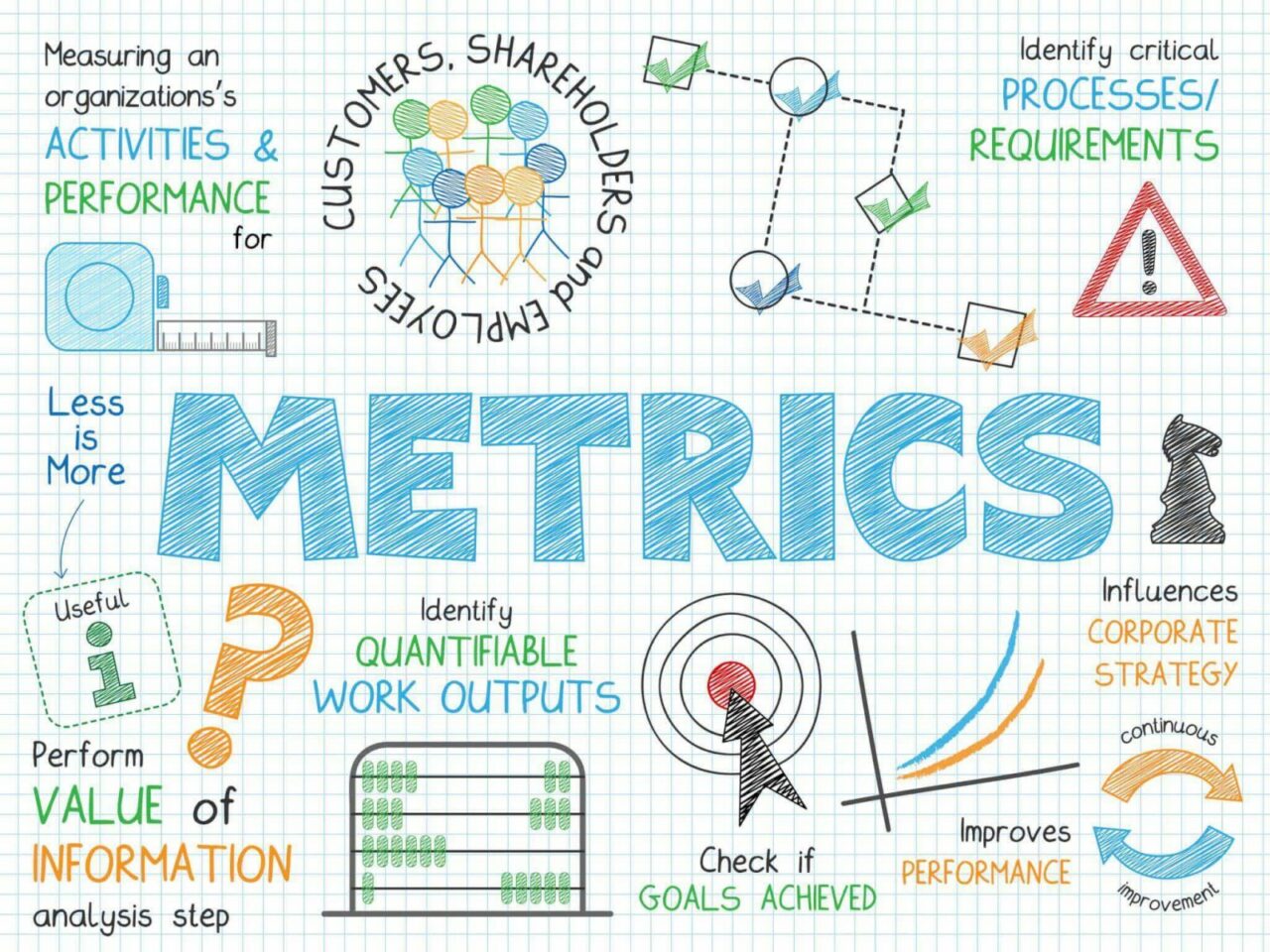

How to Develop Actionable Business Metrics

Measuring and improving performance is not just a necessity but a strategic imperative. Companies that succeed are those that not only set objectives but also track their progress and make data-driven decisions for process enhancement. This is where actionable business performance metrics come into play, serving as the compass guiding businesses toward their goals. In this blog post, we will explore how to develop such metrics in tandem with process improvement strategies, ensuring sustained growth and success.

Lean Wednesday Tip: Variation in a process

“Sources of variation can be found in the process itself, the raw materials used, the operator’s (employee’s) actions or the environment. For example, software settings / updates, tool wear, humidity, heat, and over-adjusting a machine are all sources of variation.”

How to plan a Process Improvement Project

When planning a process improvement project the most important question you have to ask is, “What problem are we trying to solve?” This question relates directly to the first step in DMAIC ( a Lean Six Sigma problem solving tool), which is to define the problem. After you answer this question you are ready toContinue reading “How to plan a Process Improvement Project”

Lean Wednesday Tip: Customer Focused Process Improvement

“Effective Lean organizations study their processes from their customer’s point of view and align their processes to meet their customers’ needs the first time and every time.” – Donna Summers

Lean Wednesday Tip

“The first step in any business process improvement initiative is to define the problem (s) but to engage in a Lean project you must have top management support.”