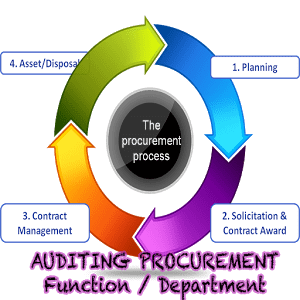

Many clients bring me in to audit their expenses and identify inefficiencies in their procurement and Accounts Payable processes. Generally, a procurement process involves the following factors:

- Current business need to purchase raw materials and supplies

- Vendor research and price comparison, including the development of a quality plan

- Approving the vendor and authorizing the purchase

- Purchasing the needed items

- Receiving an invoice

- Delivery of goods

- Inspection of goods before using (random sampling)

- Paying the supplier after quality, delivery and contract agreements have been met

From my experience, errors and waste start to creep up during the Sourcing stage as many Procurement Managers are focused on price per unit instead of the total cost. This is never the best course of action because these vendors will have to recover their costs by lowering quality, not delivering on time, et cetera. It is imperative that when conducting a procurement process audit you use random sampling to analyze purchase orders, invoices and contract agreements to ensure quantity, item description, prices, discounts and any other relative information matches. Sometimes a third party may be liable for the payment of the purchase and it was paid by the company instead which results in an unnecessary expense.

In addition, the company may have entered into a contract agreement with a freight carrier that states a guaranteed delivery, if this is not being met then the company is not liable to remit any payment.

In regards to vendors, it is also imperative that you familiarize yourself with the company’s internal controls for approved vendors. You should audit their vendor profile database in their accounting software to ensure they are legitimate and compare addresses with employee addresses to detect fraud. You should also ensure early pay discounts are being taken advantage of and that the correct discount is being applied.

It is also important to actually view the process in action and write notes about what you see. You should also speak with the employees who actually performing the activities in the process to truly understand bottlenecks and pains. After you gather this information, you should collaborate with them to create a process map to further detect inefficiencies and improve the process.

Further reading on reducing procurement costs:

How to stop freight charges from eating away at profits

Price Focused Sourcing is bad for Business