Happy Friday! I hope you’ve had a great week. Today, I want to discuss business models. As we all know, changes in trends and customer behavior affects profit. Therefore, it is important that leaders stay abreast of trends that could affect their bottom-line and have solutions at the ready. They should also include non-customers intoContinue reading “E.O.W (End of the Week) Notable Tip: Redesigning Business Models”

Author Archives: Notable Office

Lean Wednesday Tip: Variation

“Variation is attributed to what the customer sees and feels, including the best and worst performance of your product or service.”

E.O.W (End of the Week) Notable Tip: Strategic Plan Performance

Happy Friday! I hope you’ve had a great week. Today, I want to end this week with key insights on strategic plan performance. “Strategic plans should concentrate on critical success factors for the company, providing plans for closing the gaps between what the company is capable of doing versus what it needs to be ableContinue reading “E.O.W (End of the Week) Notable Tip: Strategic Plan Performance”

Reasons for Lean Six Sigma

Lean Six Sigma allows for the improvement in speed and performance of a process coupled with the reduction of waste and defects. If you ever find your current processes with high rework, client turnover, product recalls/crashes, and a plethora of errors it might be time to change your process design. As you will read below,Continue reading “Reasons for Lean Six Sigma”

Lean Wednesday Tip: C Corporation Tax Savvy

“C Corporations realize more tax savings when they lease instead of buy assets.”

E.O.W(End of the Week) Notable Tip: Quality Costs

Happy Friday! I hope you’ve had a great week. Today, I want to discuss quality costs and how they affect your bottom line. “Quality costs can be found in prevention costs; detection costs (auditing), rework, scrap, downtime and material costs. “ Effective organizations know and pay close attention to their quality costs. They invest inContinue reading “E.O.W(End of the Week) Notable Tip: Quality Costs”

Lean Wednesday Tip: Value Driven Processes

“Processes should be value driven and measured and the results carefully analyzed to identify opportunities for improvement.”

E.O.W(End of the Week) Notable Tip: Capturing Market Space

Happy Friday! I hope you’ve had a great week. Below I leave you with a short tip on capturing market space. As always, “Success is continuous improvement.” “The company that learns and adapts the smartest and fastest wins the battle of capturing new markets.”

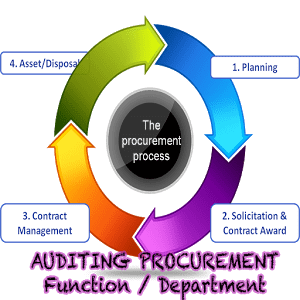

Conducting an Effective Procurement Process Audit

Many clients bring me in to audit their expenses and identify inefficiencies in their procurement and Accounts Payable processes. Generally, a procurement process involves the following factors: Current business need to purchase raw materials and supplies Vendor research and price comparison, including the development of a quality plan Approving the vendor and authorizing the purchaseContinue reading “Conducting an Effective Procurement Process Audit”

Lean Wednesday Tip: Objectives of a Process Improvement Project

“The validity of a well-planned process improvement project is identified through value-added process mapping, problem isolation, root cause analysis and problem solution. Ultimately, the key to refining processes is to concentrate on the process from the customer’s point of view and identify and eliminate non-value added activities.”