Introduction

In today’s fast-paced business environment, efficiency and productivity are paramount. Organizations strive to streamline their processes, eliminate waste, and optimize resource utilization. However, there’s a hidden culprit that often goes unnoticed – set-up time. The time it takes to prepare a machine, system, or workflow for production can be a significant source of waste. In this article, we will explore the various ways in which set-up time can lead to inefficiencies, increased costs, and reduced competitiveness for businesses. We’ll also discuss strategies to minimize set-up time and its associated waste.

Understanding Set-Up Time

Set-up time refers to the duration required to get a machine or process ready for production after a changeover. Changeovers can occur for various reasons, such as switching product types, adjusting machine settings, or transitioning between tasks. While set-up time is a necessary part of many operations, it can be a major contributor to waste in both manufacturing and service industries.

- Downtime and Lost Productivity

One of the most apparent consequences of lengthy set-up times is downtime. During this period, the equipment or process is not producing anything of value. The longer the downtime, the more potential production is lost. In a competitive market, this can lead to significant revenue losses and hinder an organization’s ability to meet customer demand.

- Increased Labor Costs

Extended set-up times often require additional labor to assist in the process. Businesses may need extra employees to help with equipment adjustments, tool changes, or cleaning. These extra labor costs can quickly add up and cut into profit margins, making the organization less competitive in the market.

- Excessive Inventory

To compensate for long set-up times, some businesses resort to building up excessive inventory levels. They produce more goods than they can immediately sell to ensure they have enough on hand during production downtimes. This leads to higher storage costs, increased risk of product obsolescence, and tied-up capital.

- Quality Issues

Set-up time can introduce quality issues, especially when machines are frequently adjusted or reconfigured. Each changeover presents an opportunity for errors or misconfigurations that can lead to defective products, rework, and customer complaints. Ensuring consistent quality becomes challenging when set-up times are lengthy and complex.

- Poor Responsiveness

In today’s market, the ability to respond quickly to changing customer demands is crucial. Lengthy set-up times can hinder a company’s agility and responsiveness, making it difficult to adapt to market shifts or sudden customer requests. This can result in missed opportunities and lost sales.

- Energy Consumption

During set-up times, machines may remain running at a reduced capacity or idling. This idle time consumes energy without generating any useful output, contributing to higher utility bills and environmental impact.

- Resource Underutilization

When machines are not running at full capacity due to frequent set-ups, their potential is underutilized. This underutilization can result in inefficient resource allocation, making it harder to achieve optimal returns on investments in machinery and equipment.

Reducing Set-Up Time and Waste

To address the issue of set-up time waste, businesses can adopt various strategies and practices:

- Standardized Set-Up Procedures: Implement standardized set-up procedures and checklists to streamline changeovers and reduce the risk of errors.

- Cross-Training: Cross-train employees to perform multiple tasks, reducing the need for additional labor during set-ups.

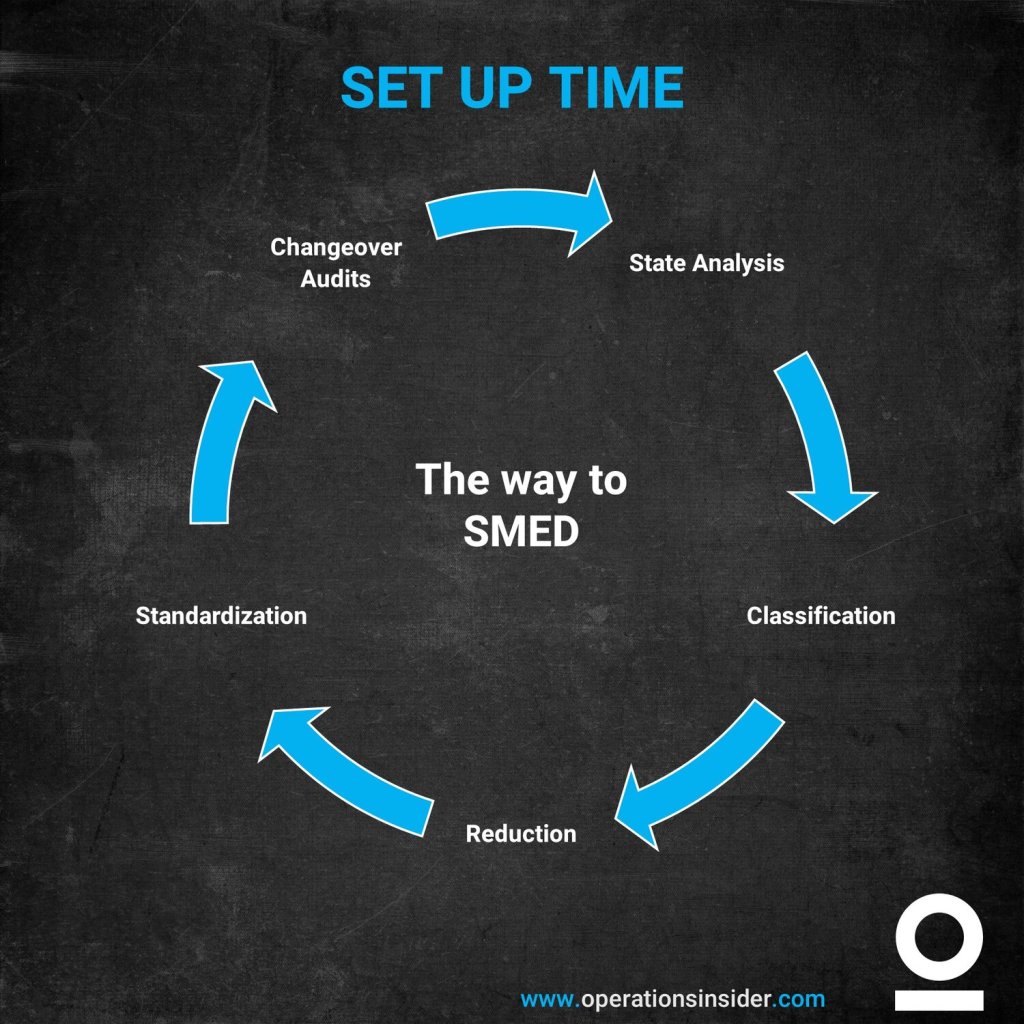

- Lean Manufacturing Principles: Embrace lean manufacturing principles, such as Single-Minute Exchange of Dies (SMED), to minimize set-up times and improve overall efficiency.

- Technology Integration: Invest in technology solutions that can automate certain aspects of set-up processes, reducing manual intervention.

- JIT Inventory: Implement Just-in-Time (JIT) inventory systems to reduce the need for excessive inventory buildup.

- Quality Control: Implement robust quality control measures to catch and rectify defects early in the production process, minimizing rework.

- Continuous Improvement: Encourage a culture of continuous improvement, where employees are empowered to identify and eliminate waste in all processes, including set-up.

Conclusion

Set-up time waste is a silent but significant contributor to inefficiency and increased costs in both manufacturing and service industries. Businesses that fail to address this issue may find themselves at a competitive disadvantage, unable to respond to market demands effectively. By recognizing the impact of set-up time on waste and implementing strategies to reduce it, organizations can enhance their competitiveness, improve productivity, and ultimately achieve better bottom-line results.

Like this post? Buy my book, Workflows: How to Design, Improve and Automate High Performance Processes to start your process improvement journey.